When a commercial laundry company came to The Insulation Guy looking for insulation work, they described their critical need for a reduction of ambient heat in the building. Additionally, this company was hoping to achieve significant energy savings.

As well as completing the insulation project for this company, we provided a routine energy savings calculation, which we are certified to provide by the National Insulation Association — which includes Owens Corning, Pittsburgh Corning, Johns Manville, and all major insulation manufacturers — in accordance with ASTM accepted standards.

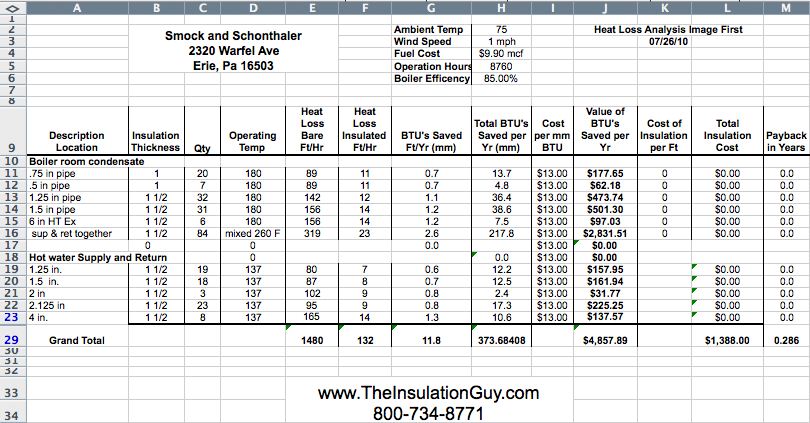

The spreadsheet below contains the audit of a commercial laundry service showing energy costs saved of $4,857.89 per year and a materials cost of $1,388 for a pay back of .286 years.

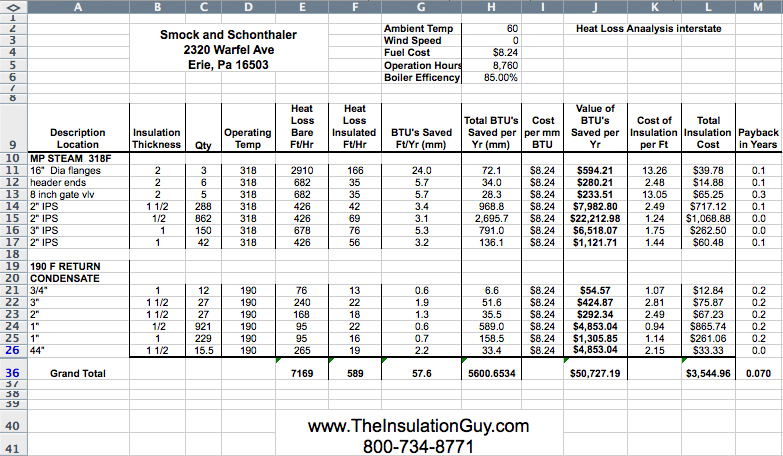

This simple survey is for a plant using steam for heating a couple of vessels and using lower pressure steam for heat. None of the piping is insulated. Material cost is $3,544.96, annual savings $50,727.19 per month. Payback .07 years.

This simple survey is for a plant using steam for heating a couple of vessels and using lower pressure steam for heat. None of the piping is insulated. Material cost is $3,544.96, annual savings $50,727.19 per month. Payback .07 years.

While we have no record of the actual ambient temperature of the laundry facility prior to our insulation work, having recorded the surface temperatures of the pipes we can show that their temperature was reduced by more than 90 percent. For example, the pipes whose surface was originally 300º F are now consistently at 90º F. This drastic change reduced the number of BTU (quantity of heat being exuded from an object) output from the bare pipe by 148,000BTW per hour.

This reduction in heat loss allowed the business owner to save thousands of dollars annually. After such success in this insulation project the owner of the laundries hired The Insulation to do another two of his businesses the following year.

Read more about how to save energy and money at your business with industrial insulation.