Industrial Insulation Shapes

Foam insulation shapes are custom made for industrial pipes, machinery, or whatever else you need to insulate. Fill the gaps left by other, less malleable types of insulation with custom foam insulation shapes specially made for your unique application. Whether you intend to insulate extremely hot or cold temperatures with custom insulation services and shapes, The Insulation Guy will produce and provide exactly what you need to reduce risk and increase energy savings.

Die-Cut Insulation Shapes Created to Fit Your Needs:

Insulation shapes are either precision machined with CNC, die-cut, or hand fabricated to fit items as small as a deck of cards or as large as a hemispherical tank head. There is no minimum size for insulation shape orders placed with The Insulation Guy. We will cut to ASTM (American Society for Testing and Materials) standard dimensions, manufacturer's drawings, or custom fit, depending on the requirements of your insulation project. These custom industrial insulation materials can be used at any temperature between -450ºF and 1200ºF.

We pride ourselves in being truly knowledgeable in understanding how to solve your application and protection problems, however simple or complex. Just call us during business hours toll-free at 800-734-8771 or complete our Contact/RFQ form.

Industrial Insulation Materials to Compliment Custom Insulation Shapes

Metal Jacketing, Fitting Covers, Bands, Screws, and Wire

Make sure your insulation shapes can withstand the test of time by protecting them with metal jacketing and additional accessories.

PVC Jacketing and Insulation Inserts

Pair custom-manufactured insulation shapes with PVC jacketing to insulate even the sharpest of angles. PVC accessories are available in a variety of sizes.

Insulation sealant and caulking

To protect insulation, create a vapor barrier and seal seams between shapes with coating cement, silicone caulking, reinforcing fabric, and breather coating.

Global Distribution of Custom Insulation Shapes

At The Insulation Guy, we understand that each and every application is unique. That is why we do not require minimum or maximum specs for custom-made insulation shapes. Each and every shape regardless of size is crafted with the highest-quality industrial insulation materials before being custom-cut to fit any application in any industrial work site perfectly.

The process starts with a custom assessment and quote where we learn about what type of insulation shape will most suit and benefit your business. Then, we will work with you to design, manufacture, and ship custom insulation shapes to your site. We ship across the United States and around the world.

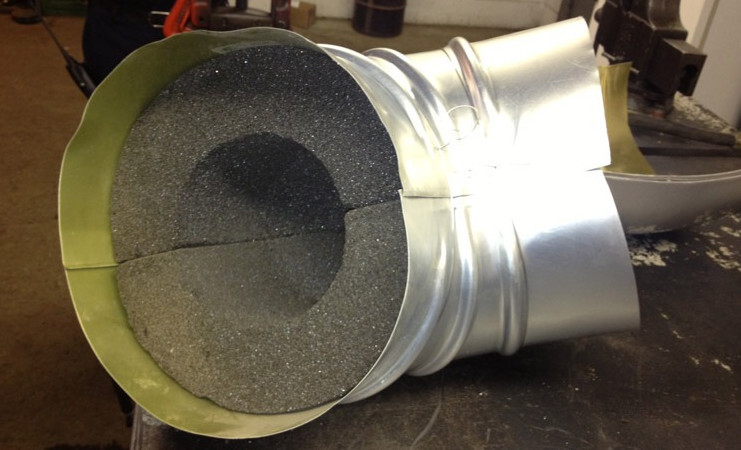

Perfectly fitted aluminum elbow over foam glass elbow

Frequently Asked Questions

Questions about custom insulation shapes? See what others are asking.

Where can custom insulation shapes be used?

Why does it matter how insulation shapes are manufactured?

How long do insulation shapes last?

How do I know what type of jacketing should be used for insulation shapes?

What else do I need to know about custom insulation shapes?

Don't see an answer to your question? Submit a question or give us a call!